Showroom

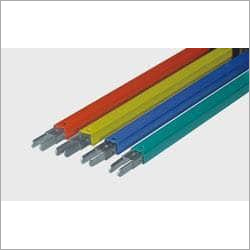

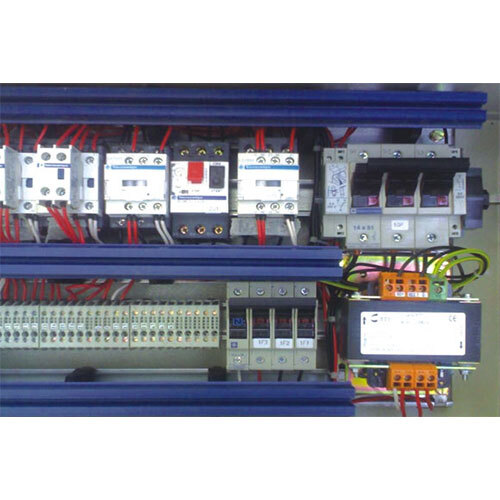

DSL System is noted as a single pole system. It has copper strips of high conductivity and is employed as the conductors for high performance. It is applicative in power & electricity distribution.

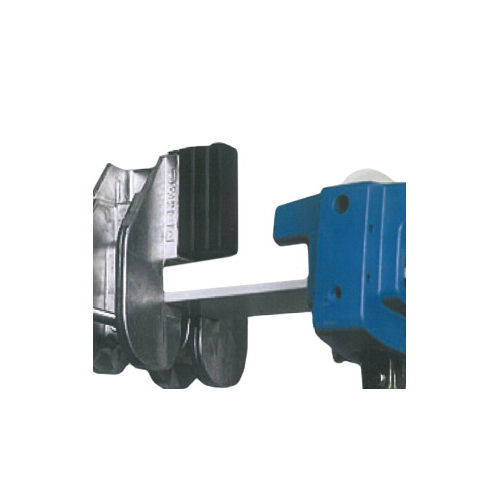

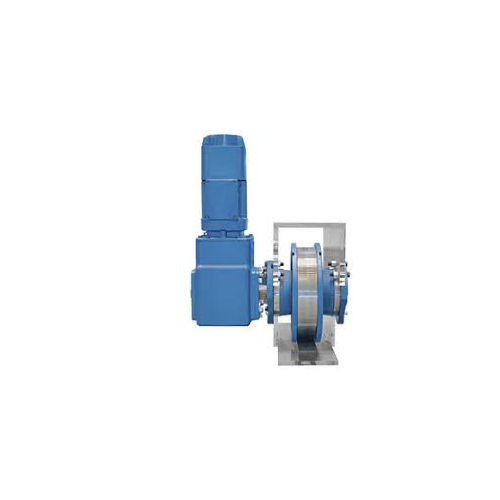

Busbar System has a protection relay that is applicative for its uses in high-impedance-based usages within industrial power schemes as well as utility substations. The system has optimal utilities in electric power distribution.

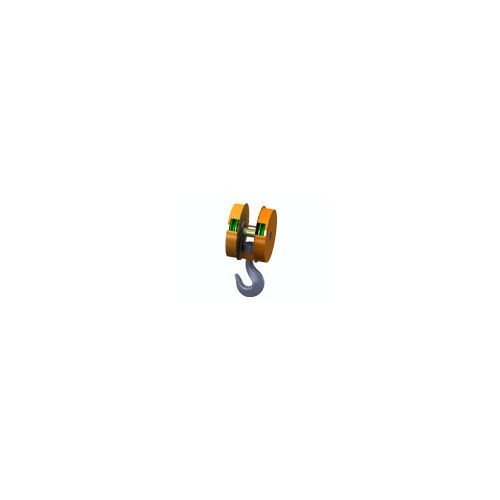

Rail Clamps are employed in numerous industries and can simply be fitted as well as installed within the machine. These clamps are employed to firmly hold the rail on to its structure without welding of the rail.

|

SILVERLINE METAL ENGINEERING PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free